Computational science

Computational Science uses physics-based models to predict the behaviour of materials and systems using high performance computing.

What is computational science?

Computational science can augment traditional research methods by accelerating and guiding experimental work and providing insight into processes and results. It is used across Shell’s businesses to help predict and understand behaviours of materials and systems in specific situations. This includes areas such as catalyst chemistry, battery performance, flow through reactors and pipelines, and more. Computational science projects at Shell involve complex simulations that require high performance computing and algorithm optimisation. The aim of computational science is to use computer models to accurately predict the performance of materials and systems. One of the most striking aspects of computational science projects is their breadth of scale. This multiscale modelling covers interactions at the atomic and molecular levels to the design of reactors in industrial plants.

Computational technology in Shell

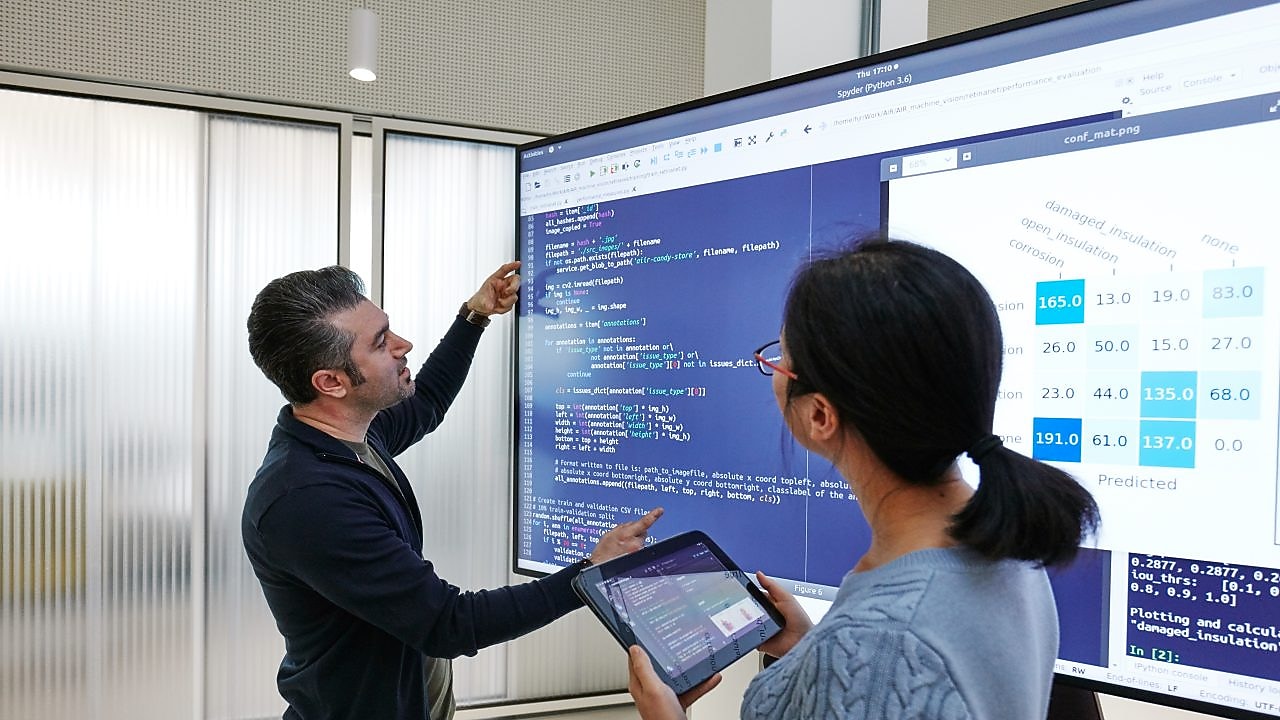

Our grasp of computational technology helped us to lead the way in technological developments in exploration in the 1960s, 70s and 80s. Demand for computational design and analysis has increased dramatically since mid-2000’s across increasingly varied domains. The growth in computer power from Moore’s law has made realistic catalyst modelling and complex fluid flow studies possible that were unthinkable only 15 years ago.

Shell has a diverse team of experts in fields such as mathematics, computing, chemistry, physics and engineering, who use computational technology to drive in developing and adopting digital technology.

Other fields of application of Computational Science

Optimal spatial planning for offshore windfarms

Computational Science researchers have developed an innovative design framework rooted in computational fluid dynamics and systems modelling to reduce the so called wake-effect in offshore wind farms. The framework integrates accurate wake predictions to inform the layout of future offshore assets. With this research, we have a better understanding of yield production of individual windmills in a farm, which enables a better economic assessment of projects as well as their optimized spatial planning.

Technology innovation for carbon capture systems

Computational science supports the development of efficient and less costly amine-based solid adsorbent sequestration technologies to capture carbon dioxide from flue gases and, eventually, directly from the atmosphere. Our researchers have developed an experimentally validated mathematical workflow based on continuum models, for analysing the carbon capture processes in a fixed-bed reactor with solid adsorbent. This research enhances experimental studies to enable quick and robust scientific exploration of better designs for Carbon capture systems.

Improving battery performance to increase potential for renewable energy and safety

Chemical storage of electrical energy is an important aspect of meeting modern energy demands. It can mitigate the intermittency and spatial variability of renewable energy availability. Combining traditional physics and chemistry with simulation and advanced imaging technology enables us to compare different kinds of batteries, not only looking at which materials perform better, but also which are more sustainable. We are looking across the end-to-end life of the battery from design and use right through to materials recovery and recycling. Shell is modelling the changes in the physical state and composition of electrodes and electrolytes in batteries as well as performance at pack level. Find out more about the research conducted with University of California Berkeley.

Optimal design for the maritime transport of hydrogen

Shell leads an international research consortium that aim to develop thermal modelling and insulation strategies for the optimal design of large-scale cryogenic hydrogen storage tanks (20,000 – 100,000 m3). This fundamental research has application for the maritime and international trade of hydrogen, which as a versatile fuel and feedstock can decarbonise different sectors. To date, there is no robust thermal and insulation property for such storage systems. Our deep understanding of thermodynamic modelling of molecules and systems integration would be a key differentiator in our contributions to this consortium. This research is sponsored by the US department of Energy.

Optimising Fuel Formulation

Shell has a long and highly successful relationship with Scuderia Ferrari. Shell leverages computational science technology to develop an advanced computer system for the Formula One fuel formulation. This system simulates a vast number of possible fuel formulations. This enables researchers to optimise fuel properties and narrow the range of possible solutions to a selection which can be tested using conventional chemical analyses in the Shell Technology Centre Hamburg, Germany. This computational pre-selection helps to accelerate the overall fuel development cycle.

Model decarbonisation pathways for hard-to-abate industries

Shell is helping to decarbonise hard-to-abate sectors of the manufacturing industry with an initial focus on cement and steel in India. ShellComputational Science researchers at our Research Centre in Bangalore, India, in collaboration with Shell TechWorks, are currently developing system-level models to help - through scenario analysis – hard-to-abate industries identify ways of improving energy productivity and reduce faster the levels of their carbon dioxide emissions. These models will provide a range of options and highlight the cost imperatives and emissions impact of the change in the operations. The models will eventually deliver insights on techno-economics factors and carbon trading options as well.

Design electrified crackers for chemicals production

Electrifying ethane cracking, one of the central processes of the chemical industry, has the potential to reducing considerably the associated CO2 emissions. Shell’s deep expertise in systems modelling and reactor design led to partnerships with Dow and the University of Houston to design novel reactors for new electric ethane crackers and find solutions to retrofit existing ones. In 2020-2021, Shell's multiscale modelling expertise contributed to securing new patents, onboarding additional research institutes in the project and securing financial support of the Dutch government.

Decarbonised gas-to-liquids production and new low-carbon energy products

Shell’s computational scientists and researchers in gas-to-liquids technologies have developed multiple system models that incorporate various technology options for the decarbonisation of GTL processes. These models also support innovation in power-to-liquids processes, which are used to generate synthetic-fuels (such as sustainable aviation fuel) and other low-carbon products (for example sustainable chemical feedstocks), which can support the decarbonisation of the aviation sectors, heavy-duty fuel applications, chemicals, cement, steel and other manufacturing industries.

You may also be interested in

Innovate with Shell

For more than 100 years, Shell has been shaping the energy industry. Today we continue to invest in innovation and entrepreneurship, both inside and outside Shell.