Augmented reality (AR) and virtual reality (VR)

At Shell, we are constantly exploring innovative technologies like Augmented Reality (AR) and Virtual Reality (VR) to unlock business value for our operations and training programmes. These technologies have the potential to enhance safety, reduce our carbon footprint, and improve efficiency across the entire lifecycle of a project, from initial planning through construction to operation.

How can AR be used in industrial operations?

Our AR Remote Assist technology enables workers in the field to receive real-time assistance from experienced technicians ("experts") from across the world. For instance, if an operational procedure requires additional guidance, a worker can get assistance via a video call, allowing the remote expert to see through their eyes and offer over-the-shoulder coaching. The remote expert can also remotely “draw” on the worker’s head-mounted screen and share relevant documentation. By working remotely, one expert can support multiple globally, resulting in quicker problem resolution reducing travel and its environmental impact.

We are also looking to expand our capabilities to improve efficiency, safety, and environmental impact using these technologies to provide guidance in everyday operations and maintenance procedures, as well as access to critical data for better work execution and safety.

We use intrinsically safe augmented reality devices mounted on helmets, which are voice-controlled and have a micro-display that shows images to the user awithout interfering with normal vision.

How can augmented reality benefit the oil and gas industry?

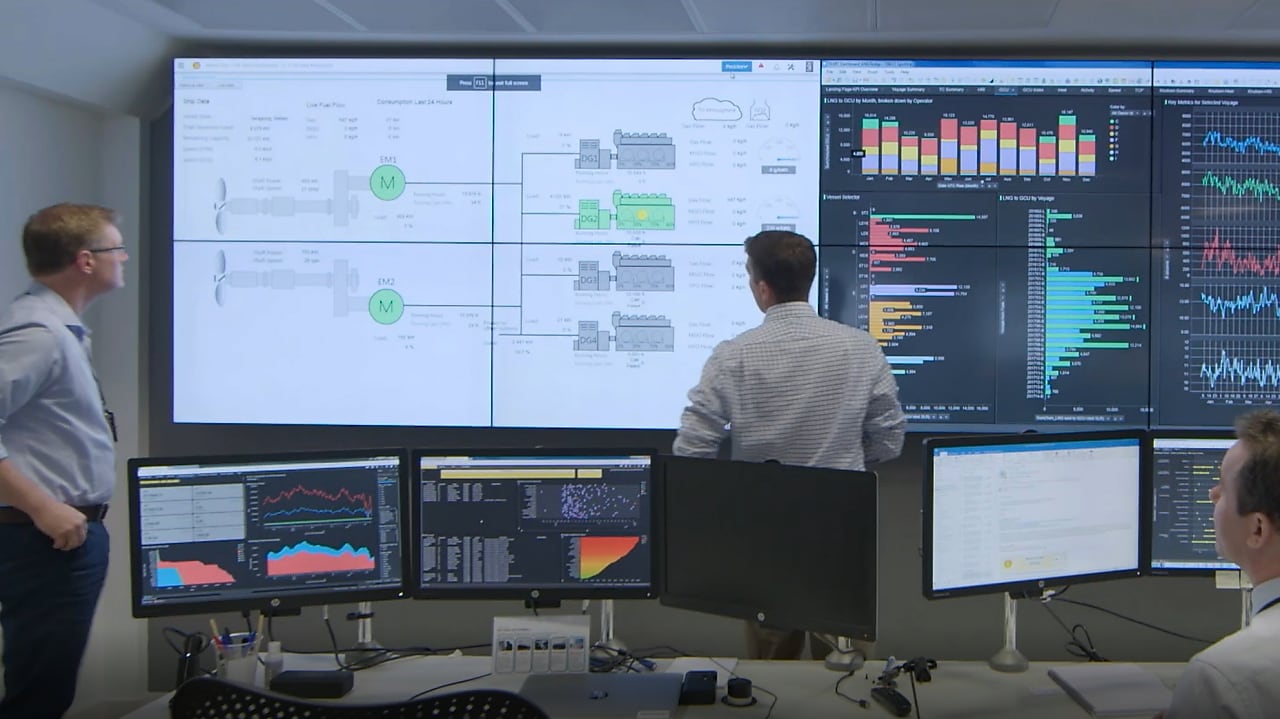

Augmented Reality can provide significant benefits to our industry by providing data and knowledge in the context of where our people are working and what they are doing. By giving AR access to data from our digitaltTwin and other asset management systems, along with Gen AI capability as a virtual subject matter expert, we may expect increased efficiency, safety, and reduced downtime associated with production impacting events.

How is VR improving training?

Shell has been using VR for training and simulation-based learning for years. VR allows users to experience virtual worlds and interact with them as if they were in that space. Shell uses VR training modules for various purposes, such as taking engineers on virtual geological field trips and training to respond to extreme events like major leaks or explosions. VR also allows transparent views equipment, such as pumps and compressors, including their inner workings.

The technology also enables collaborative discussions among team and can be used for remote conferencing and presentingcomplex 3D concepts.

Find out more about how we are using AR & VR

Our philosophy is to combine cutting edge technologies such as digital twin, generative AI, IoT, high-performance computing, AR and VR. These technologies work together to provide virtual replicas, data-driven insights, interconnected devices, swift data processing, and contribute to the realisation of an industrial metaverse.

VR for Emergency Response Training

Transforming Emergency Response Trainings within Shell Through Simulation based Learning.

At Shell, we are constantly exploring innovative ways to enhance our emergency response training and equipment installation and maintenance training. Our VR for Emergency Response Training program provides dynamic training scenarios for emergency response personnel and field operators in a simulated training environment. This program uses consequence results for leak- and fire-related incidents computed by the gas and fire dispersion modelling tool to produce scientifically accurate training simulations. Training frontline staff on the digital twin of the asset under they work helps enhance situational awareness and response preparedness.

Turn around Training in VR

Equipment installation and maintenance training for better learning and retention through VR.

In addition, we are also exploring the use of VR technologies to prepare for efficient asset turnarounds. Asset turnarounds are complex and expensive operations. Any reduction in the number of days of planned shutdown through better planning and training can result in substantial savings.

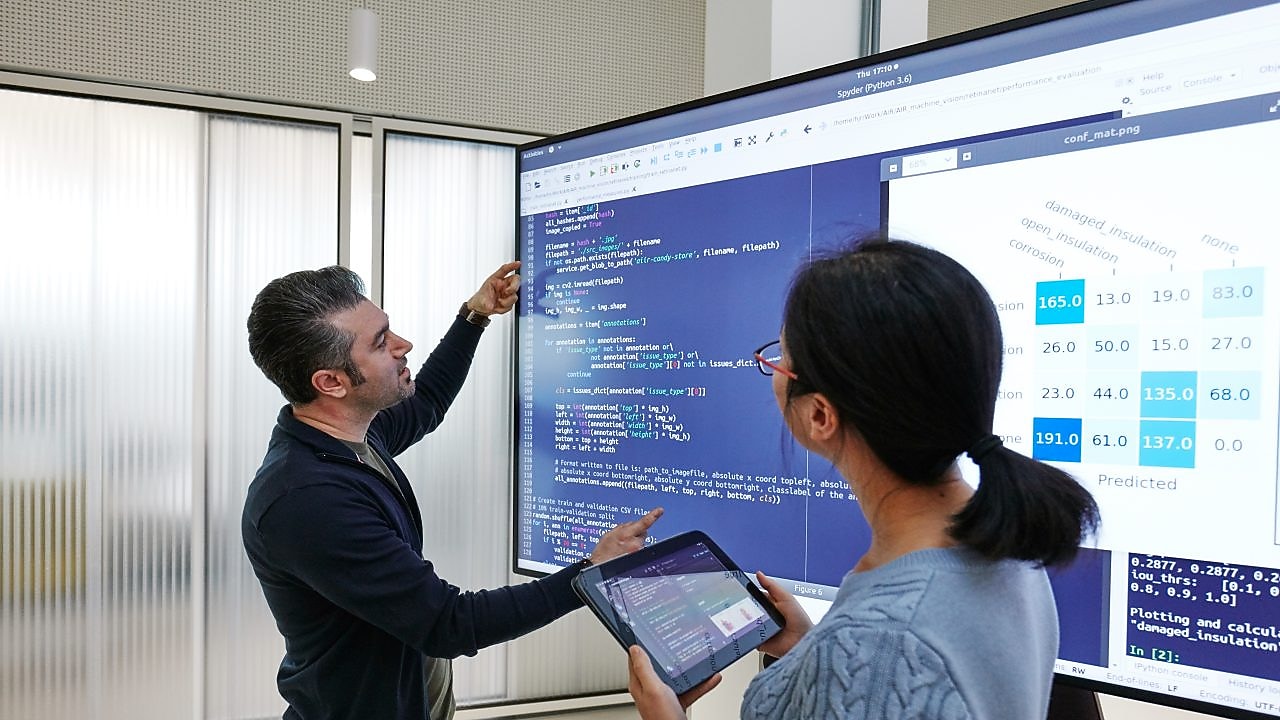

Automated modelling and analysis for rating and assessment

Furthermore, we have developed an automated modelling and analysis technology for rating and assessment. This technology is developed for rating and assessment of lubricant deposits on pistons and other engine parts after field trials. It uses advanced scientific image analyses to quantify the information and utilises 3D visualisations of the scientific data for analyses and showcase purposes.