Energy solutions for cement manufacturers

Helping to create comprehensive strategies to mitigate your plants' carbon footprint.

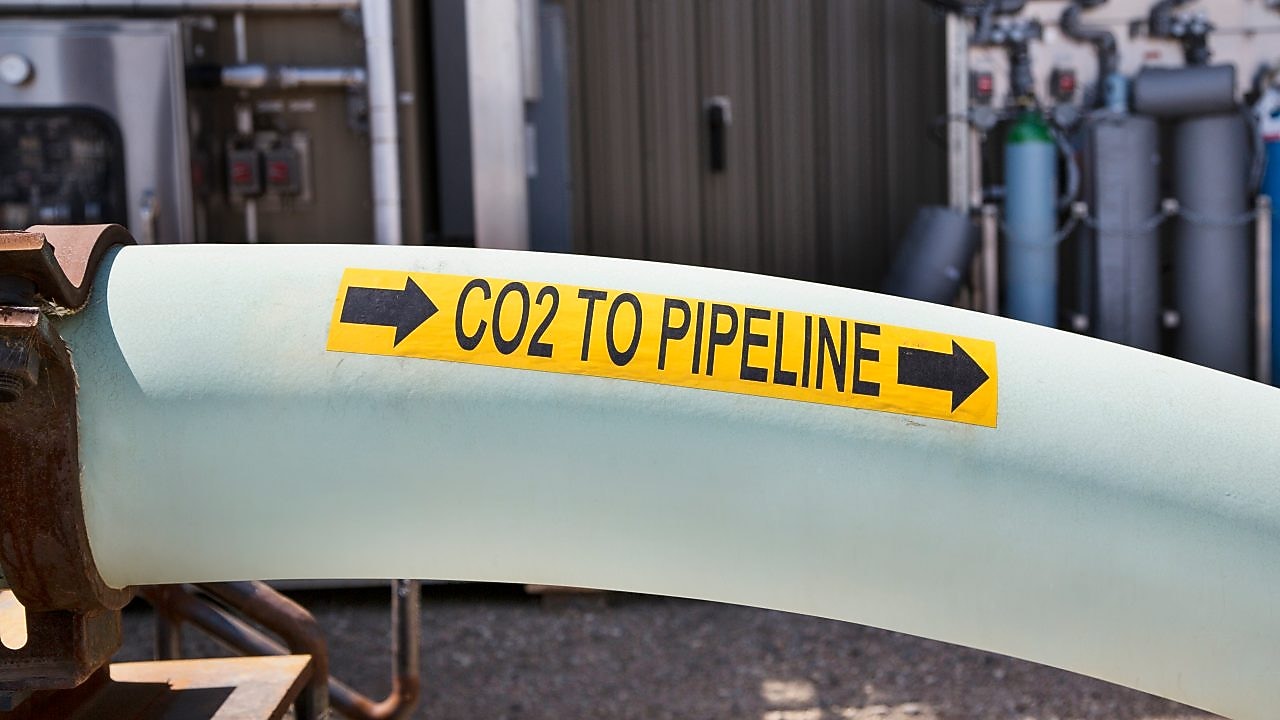

Developing integrated solutions for your plant process emissions.

Reducing plant process emissions

With the cement industry accounting for 7% of global CO₂ emissions, cement manufacturers are faced with the difficult and pressing challenge to simultaneously decarbonise whilst meeting rising global supply needs. Close to 90% of carbon emissions in cement manufacturing are from the kiln and preheater operations, which occur during thermal decomposition of limestone and combustion of petcoke to form clinker.

Through Shell's system-level modeling and partnerships with cement manufacturers, we understand that the transition to lower-carbon production and distribution will require a mix of solutions such as fuel switching, carbon capture and storage and kiln electrification.

Shell's ability to provide solutions and co-development opportunities to end-to-end cement manufacturers and clinker manufacturers can help customers achieve their decarbonisation objectives.

Watch the video to learn how Shell can help our cement customers decarbonise their operations.

How to cut carbon from cement

Read Transcript

Read Transcript

Title: How to cut carbon from cement

Duration: 4:14 minutes

Description:

Explanation of the process for cutting down carbon dioxide from the cement production industry by using capture technology to store it under the seabed with Northern Lights Joint Venture.

[Background music plays]

Up-beat music with electric guitar sounds

[Visuals]

Front, left pan, and side shot of an adult man with a high-vis jacket and a hard hat on.

Front and side shot of an adult woman with a high-vis jacket and a hard hat and goggles on.

[Text displays]

Per.

Cristel.

[Narrator]

Meet Per and Cristel.

[Visuals]

Aerial view of a cement plant.

Screen splits in two to show a front view of Cristel on the left side and a back view of Per on the right side.

Front shot of a part of the cement plant.

Key words from the audio are highlighted on top of different visuals: aerial view of a cement plant, aerial view of a dozen ships in the water, and aerial view of a shore landscape from the ocean.

[Text displays]

CO2 emissions

Cement industry

Capture technology

Specialist ships

Undersea storage

[Narrator]

They are working to cut carbon dioxide or CO2 emissions from the cement industry using capture technology, specialist ships and undersea storage.

[Visuals]

Animation of cement mixture falling from the top on a blue surface with a light blue backdrop. The cement transforms into a cube and from it, a cement-looking city model starts to emerge.

Slow zoom-out view of the cement city model and sudden drastic zoom-in to the light blue backdrop.

[Text displays]

Animation of number increasing from 0% up to 7%

CO2 emissions globally

[Narrator]

Because while cement helps build the world around us. Homes and offices, bridges and canals, roads and runways the cement industry emits up to 7% of all carbon dioxide emissions globally.

[Background music plays]

Music changes to a bright and uplifting tune

[Visuals]

Far out aerial view of a construction site by the sea.

Pan view and different close-up shots of the working site: facade, plinths, cementing.

Aerial front view of HeidelbergCement plant.

[Narrator]

So, Northern Lights, a partnership between Shell, Equinor and TotalEnergies supported by the Norwegian government, has come up with a way to help customers, like HeidelbergCement, cut them.

[Visuals]

Front shot of Per Brevik talking to the camera.

Aerial view of the plant.

[Narrator]

Per Brevik says: I feel we have a huge responsibility as one of the big emitters, but also for me as a person.

[Visuals]

Front shot of Per Brevik walking through the cement plant.

Pan shot from left to right of Per Brevik standing in front of the cement plant.

[Text displays]

Per Brevik

Director of Sustainability

Norcem

[Narrator]

This is Per Brevik, of Norcem, Norway’s biggest cement producer and part of HeidelbergCement Group.

[Visuals]

Aerial view of the cement plant.

Side shot of Per Brevik overlooking the cement plant from a platform.

Front shot of Per Brevik talking to the camera.

[Narrator]

At their Brevik plant, he’s the man with a CO2 capture plan.

Per Brevik says: We will capture 400,000 tonnes, which is 50% of our emissions.

[Visuals]

Light blue background with white text animation showing a number growing dramatically from 0 to 400,000 tonnes of CO2 per year.

[Narrator]

That’s 400,000 tonnes of CO2 emissions per year.

[Background music plays]

Music changes back to the up-beat tune with electric guitar sounds from the beginning.

[Visuals]

Close up shot of a hand holding a rock.

Front shot of Per Brevik talking to the camera while holding the rock on his left hand and cement powder on his right hand.

Close up shot of a hand holding cement powder.

[Narrator]

Per Brevik says: Cement starts with a lump of rock – limestone and it’s quite a process going from this to this.

[Visuals]

Close up shot of cement going through a machine.

Close up shot of limestone being crushed and baked.

Close up shot of the inside of a turned on pizza oven.

View of a cylinder machine in the cement plant turning.

Close up shot of small particles of calcium oxide coming out of the cylinder.

Aerial view of the cement plant chimneys releasing carbon dioxide.

[Narrator]

It sure is. To make cement, limestone must be crushed and baked at up to 6 times the heat of a pizza oven which splits it into calcium oxide and carbon dioxide.

[Background music plays]

Music changes to a gloomy mid-low vibration sound.

[Visuals]

Front shot of Per Brevik talking to the camera.

Shot of footage of the baking process being shown on a screen.

[Narrator]

Per Brevik says: This process, this split, is unavoidable. We haven’t found another way to do it without CO2 emissions.

[Visuals]

Aerial view of the cement plant.

[Narrator]

So, to stop this CO2 being emitted into the atmosphere, Per and his colleagues have come up with a clever plan.

[Visuals]

Slowly, a conceptual animation of a new building shown by light blue blocks and yellow machinery starts appearing within the cement plant.

[Background music plays]

Calm and joyful music

[Narrator]

Per Brevik says: We are building a new plant beside the cement plant where we are going to take out the CO2.

[Visuals]

Red book with a cover saying: Carbon capture and storage appears against a light blue background.

The book opens up and shows an animation of a factory. From its inside, some black particles representing CO2 start moving up the factory’s chimney but before they reach the top they are taken through a pipe to a tank. Blue drops representing water appear at the top of the tank and fall through the black particles. After touching the black particles, the liquid drops go darker and fall to the bottom of the tank.

[Background music plays]

Upbeat and joyful music

[Narrator]

And this is the technology behind it.

The CO2 emissions from the factory will be diverted into a processing unit where the CO2 molecules are absorbed by a liquid.

[Visuals]

The book changes pages and now we can see how the darker water moves to a new tank where the dark CO2 particles separate from the liquid and travel through a new pipe to a final tank with pressure and temperature valves at the top of it. The black particles fill the final tank fully and become green liquid. The green liquid lowers to half the tank.

[Narrator]

Next, steam separates the CO2 from this liquid before the CO2 is compressed at high pressure liquefying it ready for transport.

[Visuals]

Front shot of Per Brevik talking to the camera.

[Narrator]

Per Brevik says: After we have captured and conditioned the CO2 we have done our part of the work.

[Visuals]

Open book against the blue background on the page with the final tank animation with the green liquid flowing through a pipe that is feeding a green ship.

The background of the page transforms into a representation of Norway’s coastal edge and the ship moves across the page simulating the movement in the ocean going from east to west.

[Narrator]

This is where Northern Lights will come in pumping the liquid CO2 onto a ship and sailing it around the coast of Norway for permanent storage.

[Background music plays]

Fast-paced and energetic music

[Visuals]

Front and side footage of a woman using a high-vis jacket and pants, with a hard helmet and safety goggles on, walking across a bridge on a construction site.

[Text displays]

Cristel Lambton

Technical Director

Northern Lights Joint Venture

[Narrator]

Enter Cristel Lambton. Technical Director of the Northern Lights Joint Venture.

[Visuals]

Drastic zoom out from Cristel Lambton’s front shot to an aerial view of the construction site.

Front shot of Cristel Lambton talking to the camera.

Aerial view of the construction site.

Mock-up model of large storage tanks next to the coast.

[Narrator]

Cristel Lambton says: So here we are at the building site of the receiving terminal for Northern Lights, where the captured CO2 is being delivered into temporary storage tanks.

[Visuals]

Open book against the blue background showing a side view of an animation of the tanks with a pipe running from them to the bottom of the seabed. The green liquid from before flows from the tanks through the pipe. The animation shows how the pipe goes deeper and deeper into the earth below the sea until it reaches a darker layer and the green liquid spreads unevenly through that layer.

[Narrator]

From these storage tanks, the liquid CO2 will travel 100 kilometres through an undersea pipeline where it will be injected 2.6 kilometres below the seabed and stored permanently in a rock formation.

[Visuals]

Front shot of Cristel Lambton talking to the camera.

White letters against light blue background

[Text displays]

1.5 million tonnes of CO2 per year

[Narrator]

Cristel Lambton says: The capacity of phase one of Northern Lights is 1.5 million tonnes per year.

[Background music plays]

Calm and joyful music

[Visuals]

Different aerial views of the construction site.

Front shot of Cristel Lambton talking to the camera.

Close up view of a steel machine with a hot steel rod.

Close up view of a machine carrying waste and dropping it into a pit.

Aerial view of a chemical plant.

[Narrator]

Cristel Lambton says: With demand growing, we will expand the terminal to a capacity of between 6 and 7 million tonnes per year.

And this will hopefully provide a storage solution for other industries like steel, waste incineration, chemicals.

[Visuals]

Front shot of Per Brevik talking to the camera.

Animation of cement mixture falling from the top on a blue surface with a light blue backdrop. The cement transforms into a cube and from it, a cement-looking city model starts to emerge.

[Narrator]

By capturing the CO2, we can produce low carbon products and we will contribute to a low carbon economy based on sustainability.

[Visuals]

Grey background with the Shell logo inside a white circle in the middle of the screen.

Animation of the pecten growing from the centre across the screen

[Text displays]

#PoweringProgress

Copyright symbol. Shell International Limited 2022

Infographic: Decarbonising cement with CO₂ transport

Report: Decarbonising Cement with CO₂ Transport

Shell Energy, working in tandem with industry organisation Decarb Connect, has surveyed and developed a paper on the challenges and opportunities of transporting CO₂ in the cement industry.

Podcast: 1.5°C and… cement

The Energy Podcast’s Julia Streets puts hard questions to leading experts. Featuring Kristin Myskja, Director General of the Climate, Industry and Technology Department at the Norwegian Ministry of Petroleum and Energy, and Audny van Helden, former VP Energy Marketing, Sectors and Decarbonisation, Shell.