Protecting Performance

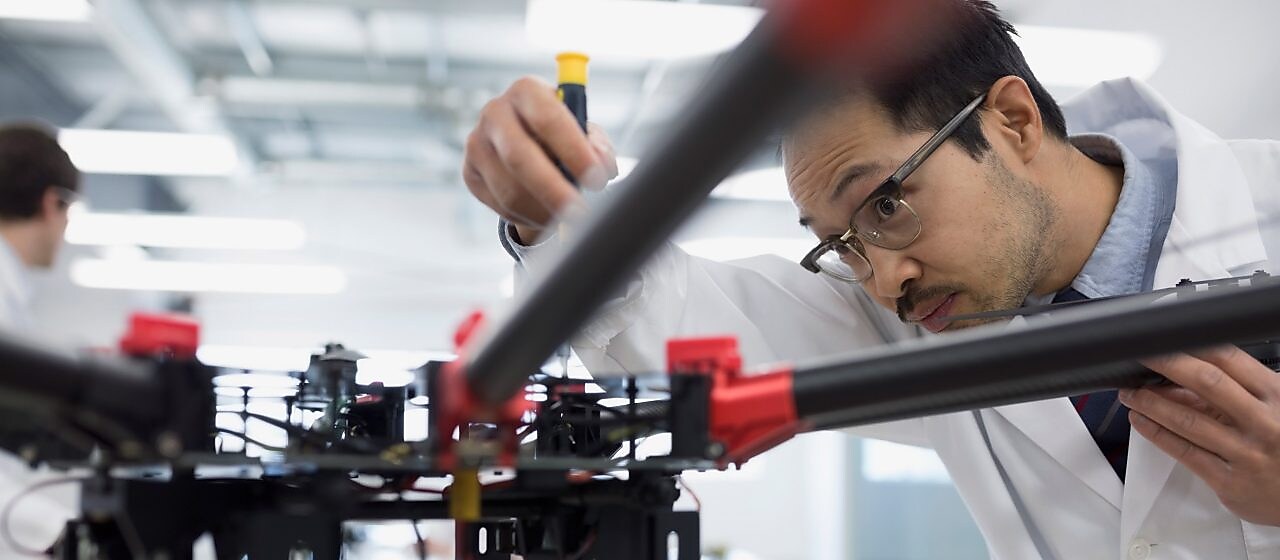

The importance of safeguarding man and machine

In the world of manufacturing, industrial robots have been helping to lower costs and speed up processes for years. But as their capabilities develop, it is not just productivity gains that automated equipment is contributing – robotics is helping to make operations a whole lot safer too.

Whether it’s by performing tasks that would traditionally pose an immediate danger to human employees or by protecting the integrity of industrial processes through greater accuracy and reliability, robotics is quickly proving its business worth throughout the manufacturing industry.

To get to this point however, the equipment itself also needs adequate protection, which is where lubricant management comes in to play.

Protecting equipment performance

Like human workers, many industrial robots are made up of a collection of joints, or more specifically, axes. The number and makeup of these axes determine the range of movement each robot possesses, which therefore has a say in which tasks they can perform while in the factory or on the production line.

For example, a robot with six axes is most able to replicate the movement of a human arm, due to its ability to move in three separate planes as well as various positions – functionality that makes it perfect for many manufacturing tasks.

However, the advantages of multiple axes are offset by their susceptibility to breakdowns should the incorrect maintenance practices be employed throughout their lifetime. This can lead to costly, unplanned downtime that risks negating the benefits of the initial investment, not to mention the potential bottlenecking of production and subsequent missed deadlines.

Fortunately, for RV applications in particular, the right grease can reduce these risks by helping to:

- Improve lubricating performance

- Maintain equipment precision and reliability

- Reduce maintenance and extend service life

And since operating environments are becoming increasingly demanding, Shell Gadus S4 V80XE 00 has been tested under real-world conditions against typical operational challenges, including:

- Load: High loads can cause surface contact, leading to wear and eventual grease and surface breakdown

- Wear: Friction not only causes wear and tear, but it slows down processes, demanding greater energy use and higher costs

- Torque: Adequate torque testing enables critical parts will not loosen or rotate unnecessarily

- Start/stop: Frequent start-stop motions generate vibration that can be difficult to protect against

- Leakage: Oil loss is a serious challenge because of grease thickening or additive loss

- Environment: Both extreme low temperatures and wet, humid environments can hinder performance significantly

- Rust: Harsh conditions or insufficient lubrication can lead to corrosion and potentially breakdowns

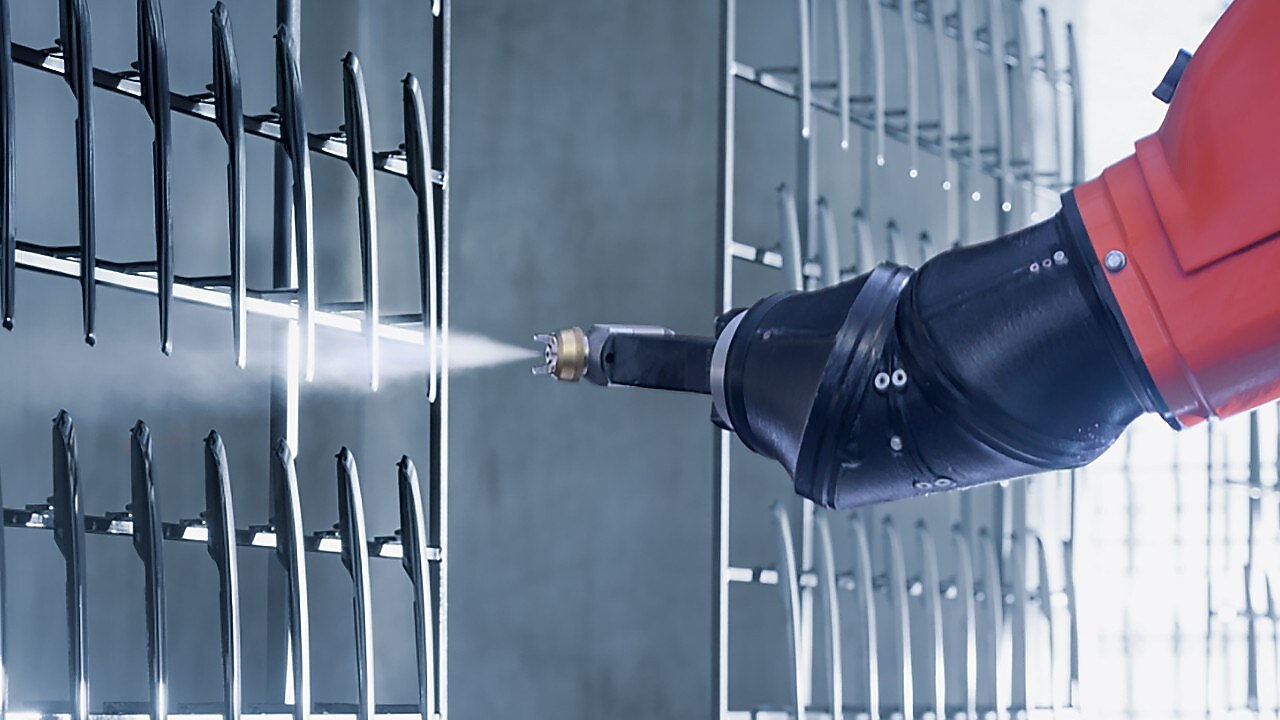

Robotics manufacturing in operation

The second piece to this puzzle is robotics ability to protect the health and wellbeing of employees, helping to address the “human exposure bottleneck” by allowing staff to work at a safer distance while retaining or enhancing process integrity. And indeed, the increasing adoption of industrial robots is not a story of human replacement, but one of co-creation and collaboration.

Despite an early notion that industrial robots were likely to replace entire human workforces, manufacturing sectors have shown that a model of collaborative robotics is perhaps the most realistic and productive. In fact, the power of Big Data and intelligent control systems means that human-robot collaboration is more common than ever.

As a result, industrial robots are taking over when their automated advantages can protect employees from the likelihood of repetitive stress injuries or the risk of major impairment. While a steady improvement in sensor technology – and its affordability – means potentially dangerous maintenance tasks can now be performed remotely. All of which points towards a future where man and machine can productively – and safely – co-exist.

Related content

Making the Future

Robotics may seem like technology fit for the future, but how do we enables it’s set up to solve manufacturers’ most pressing current issues.

5 reasons lubrication is important for industrial robots

Discover the five key ways in which effective lubrication can help shift your robotic equipment up a gear.

Assembling Partnerships

Whether it’s sharing ideas at a conference or testing them in the lab, robotics are built on collaboration. See how Shell is keeping this cooperative spirit alive.

Cautionary note

Cautionary note

The companies in which Shell plc directly and indirectly owns investments are separate legal entities. In this content “Shell”, “Shell Group” and “Group” are sometimes used for convenience to reference Shell plc and its subsidiaries in general. Likewise, the words “we”, “us” and “our” are also used to refer to Shell plc and its subsidiaries in general or to those who work for them. These terms are also used where no useful purpose is served by identifying the particular entity or entities. ‘‘Subsidiaries’’, “Shell subsidiaries” and “Shell companies” as used in this content refer to entities over which Shell plc either directly or indirectly has control. The terms “joint venture”, “joint operations”, “joint arrangements”, and “associates” may also be used to refer to a commercial arrangement in which Shell has a direct or indirect ownership interest with one or more parties. The term “Shell interest” is used for convenience to indicate the direct and/or indirect ownership interest held by Shell in an entity or unincorporated joint arrangement, after exclusion of all third-party interest.

Forward-Looking statements

This content contains forward-looking statements (within the meaning of the U.S. Private Securities Litigation Reform Act of 1995) concerning the financial condition, results of operations and businesses of Shell. All statements other than statements of historical fact are, or may be deemed to be, forward-looking statements. Forward-looking statements are statements of future expectations that are based on management’s current expectations and assumptions and involve known and unknown risks and uncertainties that could cause actual results, performance or events to differ materially from those expressed or implied in these statements. Forward-looking statements include, among other things, statements concerning the potential exposure of Shell to market risks and statements expressing management’s expectations, beliefs, estimates, forecasts, projections and assumptions. These forward-looking statements are identified by their use of terms and phrases such as “aim”; “ambition”; ‘‘anticipate’’; “aspire”, “aspiration”, ‘‘believe’’; “commit”; “commitment”; ‘‘could’’; “desire”; ‘‘estimate’’; ‘‘expect’’; ‘‘goals’’; ‘‘intend’’; ‘‘may’’; “milestones”; ‘‘objectives’’; ‘‘outlook’’; ‘‘plan’’; ‘‘probably’’; ‘‘project’’; ‘‘risks’’; “schedule”; ‘‘seek’’; ‘‘should’’; ‘‘target’’; “vision”; ‘‘will’’; “would” and similar terms and phrases. There are a number of factors that could affect the future operations of Shell and could cause those results to differ materially from those expressed in the forward-looking statements included in this content, including (without limitation): (a) price fluctuations in crude oil and natural gas; (b) changes in demand for Shell’s products; (c) currency fluctuations; (d) drilling and production results; (e) reserves estimates; (f) loss of market share and industry competition; (g) environmental and physical risks, including climate change; (h) risks associated with the identification of suitable potential acquisition properties and targets, and successful negotiation and completion of such transactions; (i) the risk of doing business in developing countries and countries subject to international sanctions; (j) legislative, judicial, fiscal and regulatory developments including tariffs and regulatory measures addressing climate change; (k) economic and financial market conditions in various countries and regions; (l) political risks, including the risks of expropriation and renegotiation of the terms of contracts with governmental entities, delays or advancements in the approval of projects and delays in the reimbursement for shared costs; (m) risks associated with the impact of pandemics, regional conflicts, such as the Russia-Ukraine war and the conflict in the Middle East, and a significant cyber security, data privacy or IT incident; (n) the pace of the energy transition; and (o) changes in trading conditions. No assurance is provided that future dividend payments will match or exceed previous dividend payments. All forward-looking statements contained in this content are expressly qualified in their entirety by the cautionary statements contained or referred to in this section. Readers should not place undue reliance on forward-looking statements. Additional risk factors that may affect future results are contained in Shell plc’s Form 20-F and amendment thereto for the year ended December 31, 2024 (available at www.shell.com/investors/news-and-filings/sec-filings.html and www.sec.gov). These risk factors also expressly qualify all forward-looking statements contained in this content and should be considered by the reader. Each forward-looking statement speaks only as of the date of this content. Neither Shell plc nor any of its subsidiaries undertake any obligation to publicly update or revise any forward-looking statement as a result of new information, future events or other information. In light of these risks, results could differ materially from those stated, implied or inferred from the forward-looking statements contained in this content.

Shell’s net carbon intensity

Also, in this content we may refer to Shell’s “net carbon intensity” (NCI), which includes Shell’s carbon emissions from the production of our energy products, our suppliers’ carbon emissions in supplying energy for that production and our customers’ carbon emissions associated with their use of the energy products we sell. Shell’s NCI also includes the emissions associated with the production and use of energy products produced by others which Shell purchases for resale. Shell only controls its own emissions. The use of the terms Shell’s “net carbon intensity” or NCI is for convenience only and not intended to suggest these emissions are those of Shell plc or its subsidiaries.

Shell’s net-zero emissions target

Shell’s operating plan and outlook are forecasted for a three-year period and ten-year period, respectively, and are updated every year. They reflect the current economic environment and what we can reasonably expect to see over the next three and ten years. Accordingly, the outlook reflects our Scope 1, Scope 2 and NCI targets over the next ten years. However, Shell’s operating plan and outlook cannot reflect our 2050 net-zero emissions target, as this target is outside our planning period. Such future operating plans and outlooks could include changes to our portfolio, efficiency improvements and the use of carbon capture and storage and carbon credits. In the future, as society moves towards net-zero emissions, we expect Shell’s operating plans and outlooks to reflect this movement. However, if society is not net zero in 2050, as of today, there would be significant risk that Shell may not meet this target.

Forward-Looking non-GAAP measures

This content may contain certain forward-looking non-GAAP measures such as adjusted earnings and divestments. We are unable to provide a reconciliation of these forward-looking non-GAAP measures to the most comparable GAAP financial measures because certain information needed to reconcile those non-GAAP measures to the most comparable GAAP financial measures is dependent on future events some of which are outside the control of Shell, such as oil and gas prices, interest rates and exchange rates. Moreover, estimating such GAAP measures with the required precision necessary to provide a meaningful reconciliation is extremely difficult and could not be accomplished without unreasonable effort. Non-GAAP measures in respect of future periods which cannot be reconciled to the most comparable GAAP financial measure are calculated in a manner which is consistent with the accounting policies applied in Shell plc’s consolidated financial statements.

The contents of websites referred to in this content do not form part of this content.

We may have used certain terms, such as resources, in this content that the United States Securities and Exchange Commission (SEC) strictly prohibits us from including in our filings with the SEC. Investors are urged to consider closely the disclosure in our Form 20-F and any amendment thereto, File No 1-32575, available on the SEC website www.sec.gov.

More about Shell lubricants

Explore our lubricants services

Explore our complete toolkit of services, gain full access to Shell expertise along with in-person and online support.

Explore our product catalogue

Explore our range of high-quality lubricant. Designed by experts, our products help in substantial savings for businesses to increase component efficiency, prolong equipment life and reduce downtime.