Efficiency in the Plant and On the Road

Boosting Reliability and Efficiency with Effective Lubrication

Whether it’s the finished vehicles or the factory production line, two key qualities are central to the operations of automotive component manufacturers: reliability and efficiency. Both ladder up to overall productivity and both can be enhanced by effective lubrication.

Lubrication on the Road

To perform reliably, the finished automotive product requires high-quality lubrication.

While operating on the road, the internal components of vehicles experience demanding conditions, including extreme temperatures and pressures that expose parts to the damaging effects of friction.

Enter lubrication. A suitable, high-quality lubricant – whether transmission oil, thermal fluids, or greases and E-greases – can dramatically reduce these effects by:

- Protecting components from wear and corrosion

- Enabling vehicles to maintain energy efficiency

- Preventing contamination that can limit performance

Getting component lubrication right from first-fill can make a lasting difference to the efficiency of the vehicle on the road.

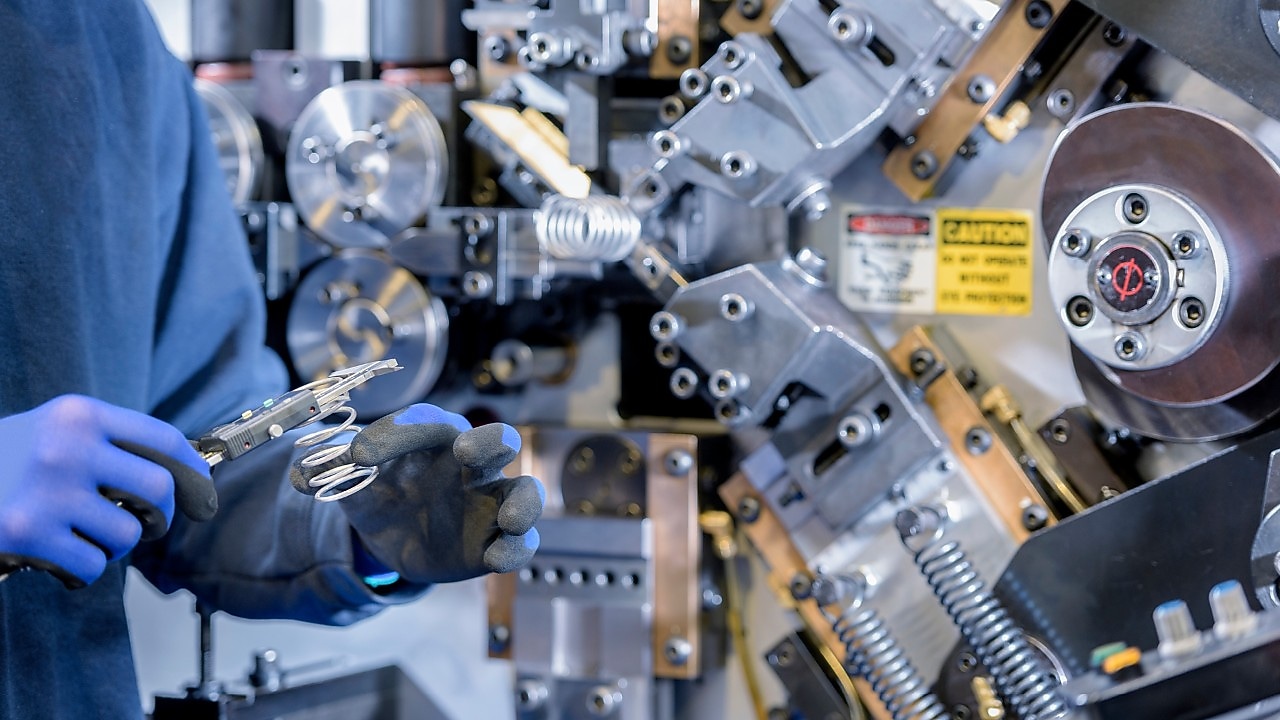

Lubrication in the Factory

Lubrication also plays an important role within the factory walls. If productivity drops in the factory, whether due to unexpected equipment downtime, inefficient processes or inadequate management, the ramifications can be disastrous.

And with robotics playing an increasingly prominent role in today’s manufacturing plants, emerging lubricant and grease technology must be able to safeguard equipment productivity by providing:

- Load carrying and wear prevention

- Protection against vibration damage

- Friction reduction

- Oil leakage avoidance

But fluid selection is just the first step in the maintenance process. For extended performance, it must then be accompanied by expert services, like oil condition monitoring such as Shell LubeAnalyst, which adds value by:

- Identifying potential oil or equipment failures before becoming critical

- Extending lubricant life and thus reducing change-out downtimes and procurement costs

- Reducing risks and contributing to safe and reliable operations

* Performance data is derived from tests in laboratories of Shell Lubricant Solutions or partners using accepted standard methods.