Shell Omala

Keep your gear operations running at peak performance

Drive system efficiency, increase productivity and reduce your total cost of ownership with the Shell Omala range of gear oils designed to help your gearboxes work harder for longer.

Extend gearbox life with enhanced protection from wear, corrosion and rust across a wide range of applications. From remote locations to extreme temperatures, the Shell Omala range is formulated to help you get the most out of your equipment in even the most challenging conditions.

Longer oil life also helps you to extend service intervals and improve productivity while reducing maintenance-associated costs.1 Whether your gearboxes are in grinding mills or wind turbines, Shell Omala helps you to maximise their potential and keep the wheels of industry turning smoothly.

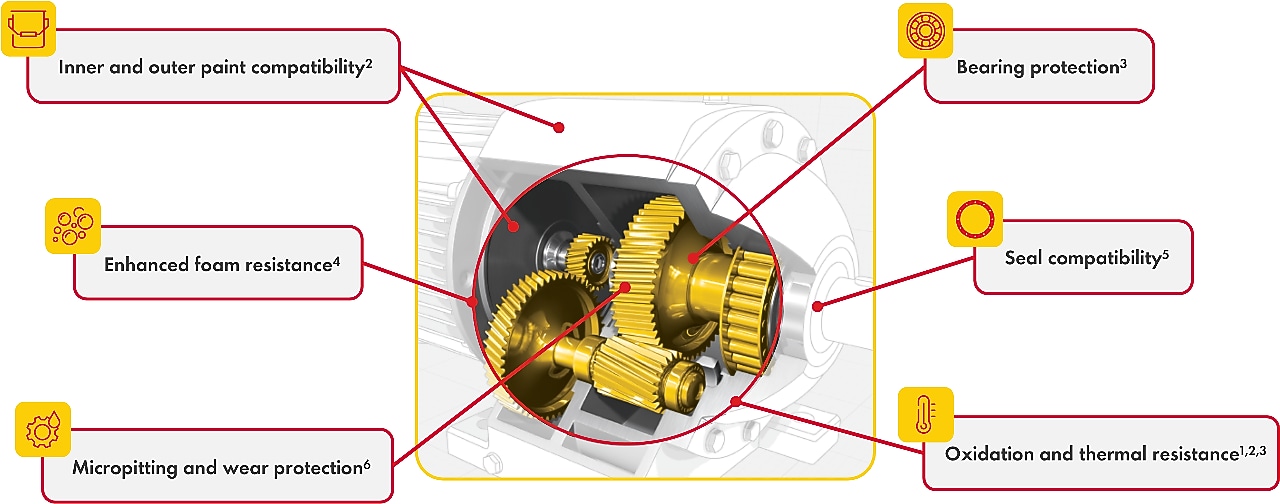

Shell Omala protects your key gearbox components

Inner and outer paint compatibility

- Meets standard test requirements with all major paint types2

- Reduces maintenance costs1

Micropitting and wear protection

- High micropitting resistance and extra wear protection6

- Extending component life and increasing reliability1

Seal compatibility

- Compatible with major seal types5

- Longer use and reduced maintenance costs1

Enhanced foam resistance⁴

- Even with contaminants or working in other severe applications

- More robust than previous formulation

Bearing protection

- Reduces roller wear1

- Low sludge tendency3

Oxidation and thermal resistance

- Longer oil life1

- Low sludge tendency to reduce blockages3

- Fewer oil and filter changes1

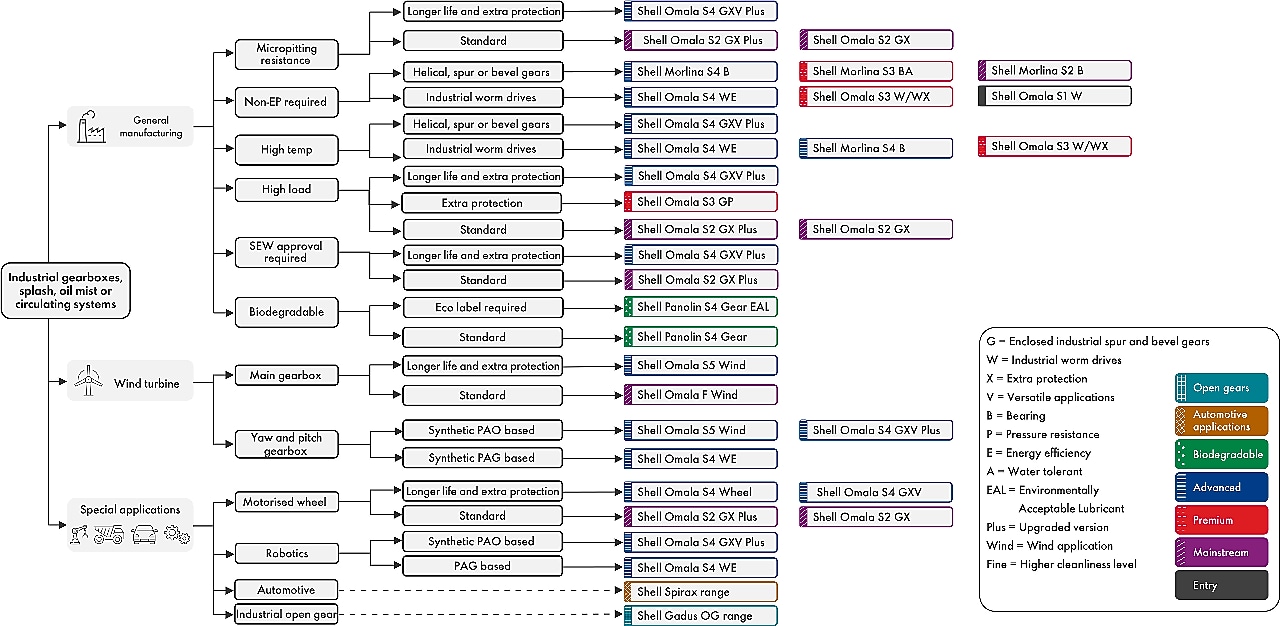

Where could Shell Omala oils add value to your operations?

Mining and cement

Conveyor, cone and gyratory crusher, shaker table, vibratory screen, separator, classifier gear, kiln and stacker reclaimer drives; draglines; shovels; rotary blast hole drills; grinding mills; dryers; ship loaders; stacker gearboxes; and bucket wheel excavators.

General manufacturing

Extruder drive and Banbury mixer gearboxes; and calendar, elevator, escalator, airport baggage handling and tunnel boring machine drives.

Oil and gas

Top drive gears; mud and fracturing pump drives; drawworks gears; crane slew and winch, and pump and compressor drives; and jack-up rig gears.

Pulp and paper

Conveyor, overhead crane, debarking drum, chipper, press section, dryer section, agitator and coating machine drives; sizing press gearboxes; paper refiners; and gear reducers in wastewater treatment plants.

Power

Coal pulveriser and cooling tower gearboxes; conveyor, and vertical and ball mill drives.

Marine

Centrifuge applications; separators; marine propulsion, crane, elevator, dredger gearbox cutting head, press suction pump and jet pump drives; winches; windlasses; and turning gears.

Metals (steel)

Overhead crane, conveyor, roughing stand, vibrating screen, and furnace table and tilt drives; screw downs; gear drive lubricating systems (hot strip, down coiler, shears and pinch roll); chains; ladle cranes; shear reducers; oil mist systems; and tension roll reducers.

Wind power

Wind turbine main gearbox and yaw and pitch drive gearboxes.

Robotic

Planetary gears, helical gears, worm gears, spur gears and special enclosed industrial gears.

Shell Omala | Product Video | Shell Lubricant Solutions

Read the transcript

Read the transcript

Title: Shell Omala | Product Video | Shell Lubricant Solutions

Duration: 1:38 minutes

Description:

This short video gives an in-depth description of the qualities and benefits of Shell Omala oils.

This video includes animations to illustrate how Shell Omala oils can offer protection across various applications.

The Shell Omala Product Video Transcript

[Background music plays]

Bright, uplifting music is played in the background.

[White screen]

A yellow droplet descends from the top to the middle of the screen, transforming into a spinning roundel. This roundel includes animations of an orange robotic arm, a white spinning wind turbine, an open gear and a grey spinning cog. There are small animations of lubricants moving and arrows around the focal roundel.

[Spoken word]

Gearboxes help keep the wheels of industry turning, but over time, they have become smaller and more intricate, while power outputs increase, and operating conditions toughen.

[Scene transition]

Next scene/frame appears

[Frame]

A zoom into the robotic arm section of the roundel – the robotic arm is making up and down movements. Then in a clockwise motion the spinning grey cog section of the roundel appears. The roundel continues to spin, changing to the vibrating open gear and finally moves to the turning wind turbine section.

[Spoken word]

Fortunately, technology advancements mean each piece of machinery is now meticulously engineered to overcome these environments.

[Scene transition]

Next scene/frame appears

[Frame]

It then zooms out to show the roundel in full – with each section of the roundel showing it's own animation. The roundel then fills in with a blue background colour and an enlarged spinning cog. The background fill of the roundel then changes to yellow and the spinning cog's appearance deteriorates.

[Spoken word]

Limiting fluid degradation can prolong oil life,

[Scene transition]

Next scene/frame appears

[Frame]

There's a zoom into the roundel that produces a new scene displaying a front-facing red car being assembled by orange robotic arms on each side, attaching wing mirrors onto the car's body. A moving yellow clock can be seen above the car accompanied by small animations of lubricants and dashed lines moving in the background. At the end of the scene, four green check marks appear one after the other at the top and bottom of the orange robotic arms.

[Spoken word]

so Shell Omala is designed to help equipment operate without interruption, enabling longer maintenance intervals, especially in heavy, repetitive industrial settings where productivity, consistency and reliability dictate success.

[Scene transition]

Next scene/frame appears

[Frame]

A roundel appears in the middle of the screen, obstructing the red car and the clock but leaving the two orange robotic arms in view. The roundel contains a blue background fill and displays two animations of grey spinning gears. The background fill of the roundel then changes to yellow and the animation of the gears deteriorates simultaneously.

[Spoken word]

The enhanced wear protection provided by Shell Omala safeguards gears against service life and productivity drains.

[Scene transition]

Next scene/frame appears

[Frame]

There is a blue sky with 3 spinning wind turbines planted in a darker blue ocean. There is an animated dashed line that shoots off-screen. 3 bubbles appear one after the other next to the 3 wind turbines. The first appears on top of the middle turbine, the next appears on the right of the right turbine and the last appears on the left of the left turbine. These bubbles begin to fill with a yellow and a green outline in the same order, revealing green icons. The first reveals an icon representing a kilogram weight, the next reveals a snowflake icon and the last reveals an icon representing chemical corrosion.

[Spoken word]

Take modern wind turbines. Their bigger blades are increasingly asked to work harder, meaning critical components come under strain from higher loads. Between isolated locations and harsh operational conditions, gear oils demand a balanced performance – all of which starts with protection.

[Scene transition]

Next scene/frame appears

[Frame]

The scene then zooms past the 3 wind turbines, transporting to 3 onshore spinning wind turbines planted on green forest terrain with a blue sky. There are numerous green turbines spinning in the background.

[Spoken word]

By maintaining an adequate lubricant film,

[Scene transition]

Next scene/frame appears

[Frame]

The scene then zooms past the 3 wind turbines, transporting to 3 onshore spinning wind turbines planted on brown desert terrain with a blue sky. There are numerous brown turbines spinning in the background.

[Spoken word]

an oil like Shell Omala keeps oil flowing while flushing out contamination.

[Scene transition]

Next scene/frame appears

[Frame]

The scene then zooms past the 3 wind turbines, transporting to a new scene displaying an animated tractor, a dump truck and a wheeled loading shovel moving on a yellow terrain with a blue sky.

[Spoken word]

Even amid extreme conditions, like those experienced in the mining industry, where dust, high temperatures and rain all test viscosity and pumpability.

[Scene transition]

Next scene/frame appears

[Frame]

A roundel split into 4 sections appears on a white background. This roundel includes animations of an orange robotic arm, a white spinning wind turbine, an open gear and a grey spinning cog. There are small animations of lubricants moving and arrows around the focal roundel.

[Spoken word]

Shell Omala oils have been formulated to provide everything you need to keep the wheels turning

[Scene transition]

Next scene/frame appears

[Frame]

The dark grey animated container representing the Shell Omala product appears in the middle of the roundel. The product is zoomed into and becomes larger, resulting in the disappearance of the roundel. There are small animations of lubricants moving and arrows around the focal product.

[Spoken word]

and your business on track.

[Scene transition]

Next scene/frame appears

[Frame]

The Shell Omala product then shoots left off-screen, revealing the "Shell.com/Omala" text in red.

[Spoken word]

Speak to one of our experts or visit Shell.com/Omala to find out more.

[Scene transition]

Next scene/frame appears

[Background music plays]

Shell Jingle

[Animated Sequence]

Shell Pecten logo sits on the frame.

Key Benefits ₁

Improve gearbox reliability¹

Protect your gearbox components from wear and contamination, helping you to drive reliable equipment operations.

Reduce maintenance downtime⁷

Extend oil-drain intervals to maximise the potential of your equipment and lower the associated maintenance costs.

Enhance system and energy efficiency⁸

Increase productivity with effective lubrication that helps your equipment meet its capabilities and reduce total cost of ownership through enhanced energy efficiency.

Increase load carrying capacity⁹

Extend the life of components by protecting them, even in arduous low-speed, high-torque working conditions.

Shell Omala Family brochure

Creating value by keeping industrial spur and bevel gearboxes and worm gears operating efficiently for longer, even in severe applications and challenging operating conditions.

Shell Omala S4 GXV Plus

Advanced synthetic industrial gear oil approved by SEW and Flender.

Shell Omala S4 WE

High-performance, PAG-based full synthetic industrial gear oil for bronze-on-steel worm gears.

Shell Omala S2 GX

High-performing industrial gear oil approved by key OEMs.

Disclaimers:

1 Compared with industrial standards and conventional gear oil in the market, based on Shell internal laboratory results of standard wear and corrosion tests.

2 Proven by the internal and third-party laboratory compatibility tests.

3 According to the oxidation and sludge tests, compared with industrial standards.

4 Shell Omala S4 GXV Plus has less foam volume in the Flender foam test compared with Shell Omala S4 GX and four competitor oils tested. Neat Fluid at 25°C. All fluids ISO 320. Based on Shell internal competitor benchmarking tests.

5 Static (ISO 1817) and dynamic (DIN 3761) testing with a wide range of seal materials.

6 FVA micropitting test No. 54/VII with Shell Omala S4 GVX Plus 150, based on Shell internal tests results.

7 In the industry-standard oil life test, Shell Omala S4 GXV Plus achieved up to 67% less thickening than the maximum allowed after 312 hours at 121°C to ensure efficient and consistent lubrication.

8 FVA 345 test using a modified FZG test rig with two gearboxes connected back-to-back allowing for the precise measurement of energy losses across a wide range of speeds and loads. Shell Omala S4 GXV Plus 320 was tested against a conventional mineral oil of the same viscosity. An average 3.6% better energy efficiency was recorded based on three runs with each oil.

9 Compared with industrial standards and conventional gear oil in the market, based on Shell internal laboratory test results.

For more product-specific information, please visit www.epc.shell.com for more details.