Aromatics Complex Catalysts

Shell Catalysts & Technologies offers a portfolio of catalysts to add value throughout the aromatics complex. This includes next-generation trans-alkylation, ethylbenzene dealkylation (EBD), ethylbenzene reforming (EBR) and paraffin isomerisation catalysts that offer standout activity and selectivity, enabling operators to optimise plant economics and reduce their carbon footprint.

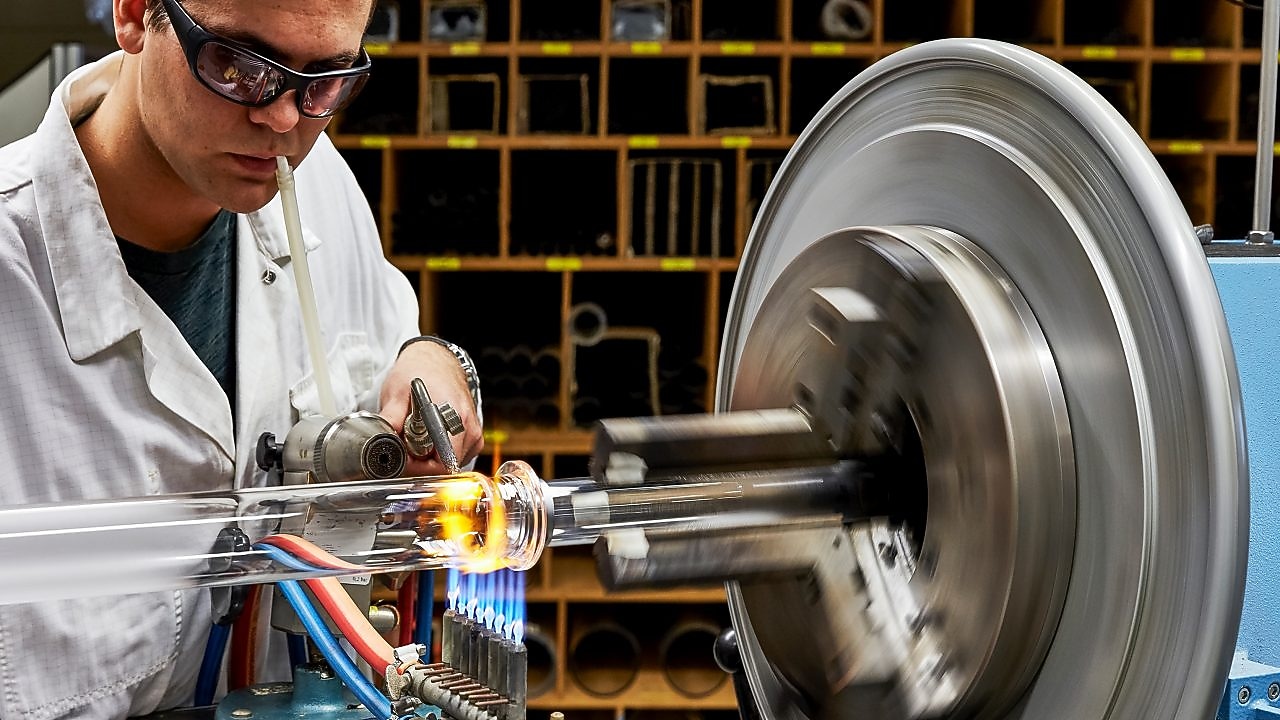

Aromatics catalysts can help deliver high activity & selectivity through molecular engineering

As a result of extensive research and development, Shell Catalysts & Technologies has developed a range of aromatics complex catalysts that feature engineered zeolites and novel metal functions. These features result in very high selectivity, providing minimal ring loss and reducing hydrogen consumption.

As robust systems, the aromatics catalysts offer high conversion rates at lower temperatures which leads to longer cycle lengths. Lower light hydrocarbon formation contributes to lesser value loss while higher catalyst activity lowers energy consumption. The aromatics portfolio catalysts can therefore help plant owners meet their commitments to eliminate or reduce such emissions at their facilities and improve sustainability.

For paraffin isomerisation, our latest-generation, low-density, high-activity catalyst ensures high throughput for high isomerate yield, with less cracking and hydrogen consumption.

Trans-alkylation

Trans-alkylation

ATA-21Next and ATA-41 catalysts are used in aromatics complexes in the toluene disproportionation or trans-alkylation unit when conversion of toluene and C9+ aromatics to mixed xylenes and benzene is required. Processing C9+ aromatics in a trans-alkylation unit shifts the chemical equilibrium away from benzene production and towards xylene production. The trans-alkylation process provides a means of producing more mixed xylenes from low-value toluene and heavy aromatics. The incorporation of a trans-alkylation unit into an aromatics complex can more than double the yield of paraxylene from naphtha feedstock.

The ATA series is an established leader in trans-alkylation offering highly stable performance in the treatment of heavy feedstocks and a 20+ year track record. In that time 1,700 tons has been loaded into 31 units, with a zero-failure rate on start-up or in operation.

Ethylbenzene dealkylation

Ethylbenzene dealkylation

ZATARIS-21 is an EBD catalyst, deployed as a dual-bed catalyst system, with high activity. It offers low hydrogen consumption and almost 100% aromatic ring retention, making it well suited to low-paraxylene feeds.

As a drop-in solution, ZATARIS-21 furthers the decoupling of EBD and xylene isomerisation functions, thus promoting exceptional preservation of the aromatic content of the feed while offering high activity for reduced energy consumption. Depending on the feed, operating conditions, product requirements and profit considerations, the ratio of each catalyst per bed can be tailored to provide greater feed flexibility.

Ethylbenzene reforming

Ethylbenzene reforming

OparisNext is the latest-generation EBR catalyst for paraxylene producers looking to maximise margins and strengthen their competitive position. It is used in aromatics complexes when conversion of ethylbenzene to xylenes is required, in combination with isomerisation of xylenes into the equilibrium composition.

OparisNext contains the latest patented zeolite technology, which is based on more than 30 years of EBR operations. In that time, the Oparis series of catalysts has been loaded in 26 units and never had a failure on start-up, or in operation, and has had 20+ successful regenerations.

Paraffin isomerisation

Paraffin isomerisation

ATHOS-3 is the latest-generation paraffin isomerisation catalyst that is used for the treatment of light straight-run naphtha streams to produce a high-octane gasoline blending component. The catalyst offers lower operating temperatures, or higher throughput at similar temperature, when compared with previous generations. Operating at lower temperatures brings the benefit of saving energy, boosting octane number and maximising liquid yields.

This same technology can be re-purposed to reverse isomerisation if straight chains are required.