Shell Grade Monitor Improves Fuel Safety

Even with the highest standards of operational diligence among aircraft refuelling teams, human errors can occur. In some instances these can lead to an aircraft receiving the wrong fuel, or fuel contaminated with other fuel of a different grade.

Such errors, although very rare, are more likely to occur at smaller airports, with similar and adjacent storage tanks for Jet A-1 fuel and Avgas, or where it is not economical to have separate fuel trucks for different grades of fuel. Contamination or simply using the wrong fuel can cause engine problems and even lead to serious accidents.

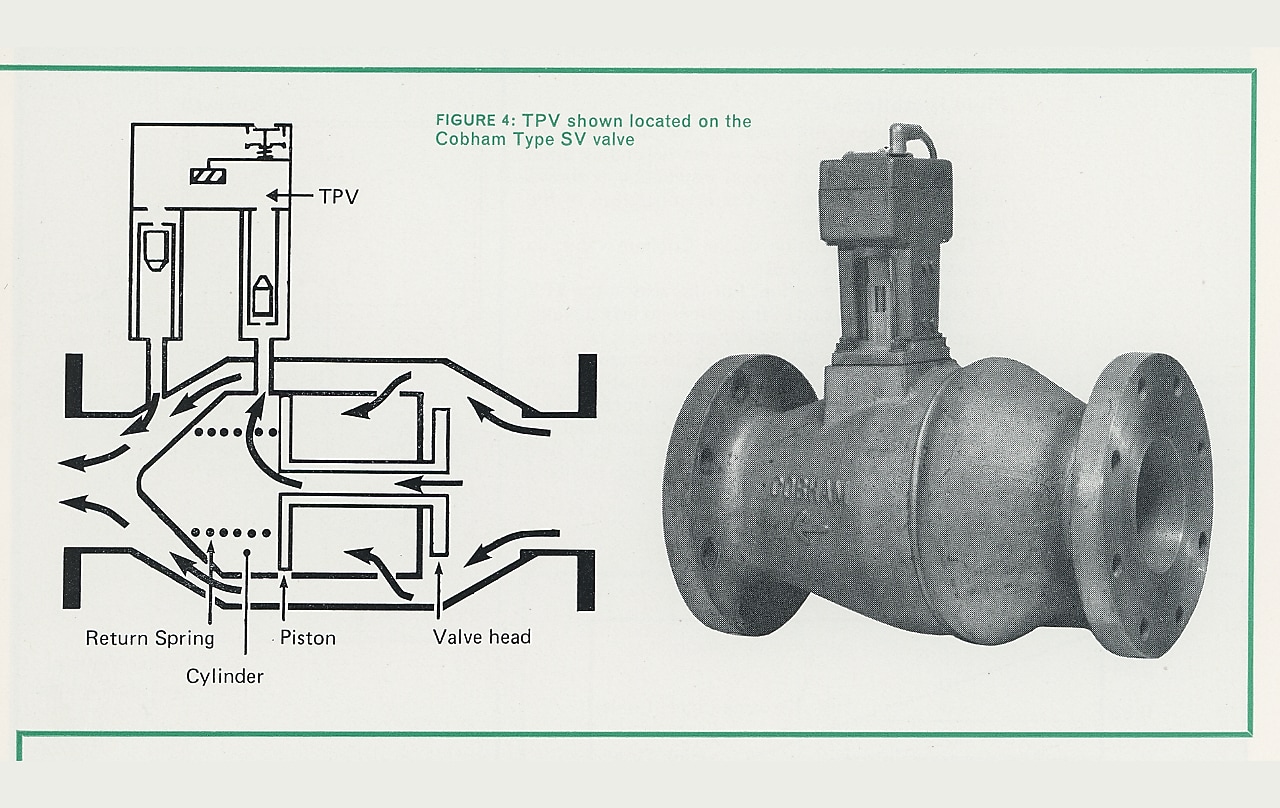

As aviation expanded, connecting more and more smaller communities, Shell Aviation recognised this problem. In the 1970s, it developed a simple, fail-safe automatic grade monitor device, which was easy to install and operate at smaller airports. The device identified the fuel grade and shut down the supply system when an unacceptable fuel was detected. A proprietary servo-controlled valve, called the Thornton Pilot Valve, was central to the monitor, which was installed at fuel storage depots.

The device helped the aviation industry achieve higher standards of contamination control and make a significant contribution to improvements in fuel quality assurance and flight safety.

Shell has continued to work with partners across the aviation industry to improve the safety of aviation refuelling. In 2020, it rolled out Shell Jet Protection across its fleet at all Shell managed sites. This new approach to safe fuel filtration removed the need to use superabsorbent polymers or SAP (similar to materials used in diapers) to remove water contamination. Industry studies, supported by Shell, had identified that, under certain circumstances, the SAP from the filters could migrate into the fuel tanks and engines of aircraft, with the potential to cause serious issues.

Sources:

Shell Aviation News, 1976, p. 172-176.

DEVELOPING AN AUTOMATIC GRADE MONITOR FOR AVIATION FUELS | Semantic Scholar

https://www.shell.com/business-customers/aviation/aviation-fuel/why-choose-shell-jet-protection.html

Shell historical archives.

Decarbonising Aviation: Cleared for Take-off

Our new report, produced with Deloitte, reflects views from right across the aviation industry on the obstacles the sector faces and provides a clear pathway for the sector to accelerate progress towards net-zero emissions.